PRODUCT DESCRIPTION

Technical side

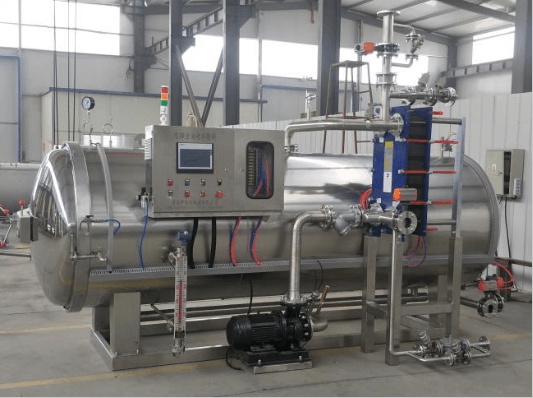

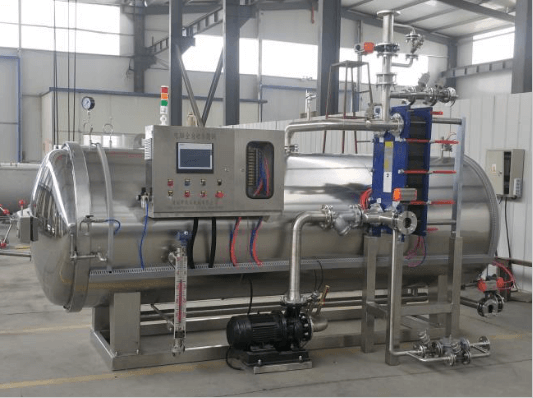

Hs-1300 automatic water bath + spray sterilization kettle

Factory photos

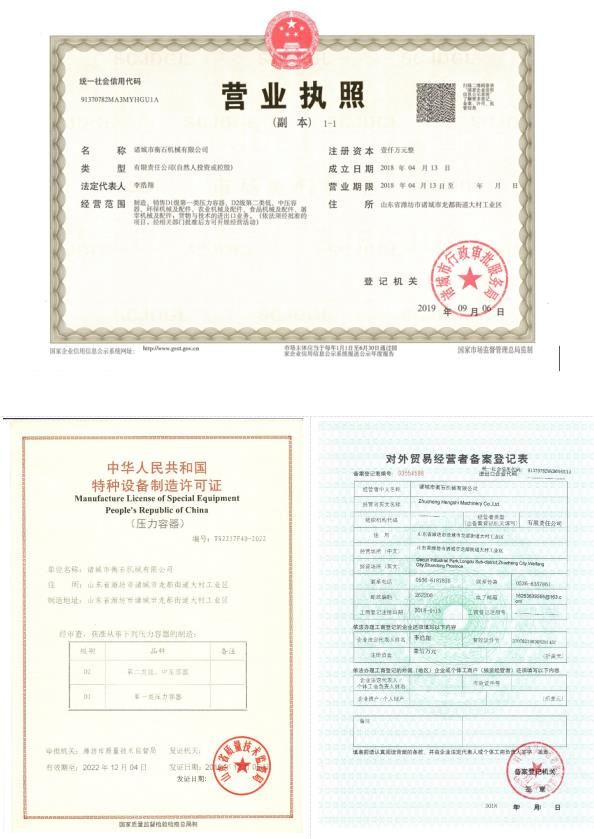

Corporate information

Quality

Computerized automatic water bath/spray sterilization single pot(The product sample picture shows, does not represent this custom-made product)

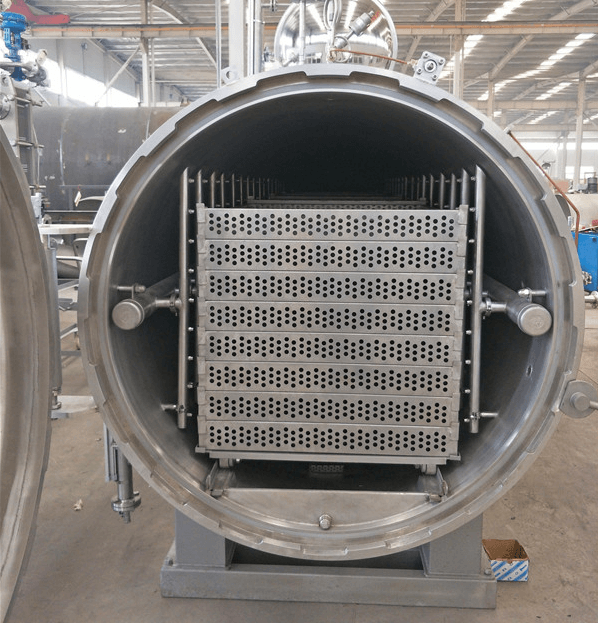

| The picture |  |  |

| The name of the | Sterilizing plate (flexible packaging) | Revolving cars |

| brand | HengShi | HengShi |

| place of origin | zhucheng | zhucheng |

| function | Store the sterilized material | Store the sterilized material |

| The picture |  | |

| The name of the | Pallet car | |

| brand | Baofeng | |

| place of origin | zhucheng | |

| function | Store the sterilized material |

一、Sterilization pot configuration and price part

| The name says | Gauge | unit | quantity | unit price | Price (¥) |

| Fully automatic steel water bath + side spray sterilization pot | DN1300×4500 | Taiwan | 1 | 248000 | 248000 |

| Antiseptic dish(S30408) | 880×900×145 | a | 30 | ||

| Supporting plate(S30408) | Match the sterilizing plate | a | 5 | ||

| Revolving cars(S30408) | Match the pallet truck | car | 5 | ||

| A combined: | Renminbi in words: Two hundred and forty-eight thousand Only | ||||

| note: | Tax is not included FOB is not included | ||||

Note:

1. Valid time of quotation: 15 days

2. Place of delivery: Buyer

3. Transportation cost: The seller shall bear the freight

4. Transportation time: to be determined

5. Payment term: according to the contract

6. Delivery time: to be determine

Sterilization pot function parameters configuration table

1、Main parameters of a single device

| project | Within the capacity |

| Sterilization pot inside diameter/tube length/full volume | 1300 mm /4500mm /6.46m3 |

| Design pressure/maximum working pressure | 0.35 Mpa/0.3 Mpa |

| Design temperature/operating temperature | 147℃/143℃ |

| Total installed power | About 11KW (circulation pump 11KW) |

| The power supply voltage | 380V,50Hz |

| Sterilization plate size (length/width/height)mm | Outer size :880*900*145mm, wall thickness: 1mm |

| Sterilization pot body material/wall thickness | S30408 stainless steel/wall thickness 5mm |

| Sterilization yield and meat product calculation | About 1200 kg/per pot |

| Equipment floor space size | About 6500 * 1950 * 2200 mm |

2、Conditions of Use (provided by the user of the ancillary equipment)

| project | Within the capacity |

| Total power | Capacity ≥13KW/ voltage 380V/ frequency 50HZ |

| The water quality | The cooling water is tap water, and the chlorine ion content in the water is not higher than 25mg/L. Cooling water temperature ≤25℃. |

| Air compressor | The air output was 2.0m3/ min and the pressure was 0.8Mpa |

| Compressed air storage tank | The volume is 2m3 and the pressure is 1.0mpa |

| Cooling water tank | 11m3 |

| Cooling tower (optional) | 40T/H |

| Boiler type/minimum boiler pressure | About 1.0 T/h / 0.6 Mpa |

3、Energy consumption per unit

| project | Within the capacity |

| Electric power | About 11 kw · h/pan |

| steam | About 400 kg/pan |

| The sterilization of water | About 6.0 m after/time |

| Cooling water | About 11.0m/time (secondary cooling is generally used) |

4、1300Type I computer automatic water bath/spray sterilization kettle main configuration

| The name of the | specifications | The number of | The material | Origin of the brand | note |

| Sterilize the pan | 1300*4500*5 | 1a | Gb container plate S30408 | HengShi company | Design pressure: 0.35mpa Working pressure: 0.3Mpa Design temperature: 147℃ Working temperature: 143℃ Test pressure: 0.44mpa |

| head | DN1300*5 | 2a | S30408 | Jiangsu is correct | Integral thermal spinning |

| flange | DN1300 | 1 set of | S30408Ⅱ | Zhgqiu baohua | No welding for integral forging |

| Pan door gasket | DN1300 | 1 set of | The silicone | HengShi company | Seal pan door |

| Elbow and interlock assembly | DN1300 | 1 set of | compound | HengShi company | Pan door switch, load bearing |

| Saddle assembly | DN1300 | 1 set of | compound | HengShi company | Pot body connection, load bearing |

| Lug device | DN1300 | 1 set of | Stainless steel | HengShi company | Equipment hoisting |

| Thermal insulation layer | DN1300 | 1 set of | Aluminum silicate | HengShi company | Heat preservation and heat insulation |

| Circulating pump | 11 kw power High temperature resistance above 130℃ | 1Taiwan | ---- | Shanghai bihu | Circulating process water sterilization |

◆Electrical control part

| The name of the | specifications | place of origin | The number of | function |

| Stainless steel electrical control box | Hengshi | zhucheng | 1a | Installation of electrical components |

| The man-machine interface | Siemens | Germany | 1 set of | Input instruction, display the working status |

| PLC | Siemens | Germany | 1a | Sterilize the main controller of the pot |

| Temperature module | Siemens | Germany | 1a | Control temperature section |

| Pressure module | Siemens | Germany | 1a | Control pressure section |

| Output module | Siemens | Germany | 1a | The signal is transmitted to the branch circuit |

| Pressure sensor | HUBA | The Swiss | 1a | Measure the pressure in the pot |

| PT100 | YunQi instrument | shandong | 2a | Measure the temperature inside the pot |

| Solenoid valve | Effective west | zhejiang | 14a | Control various valves |

| Ac contactor | schneider | The French | 1a | Control pump motor |

| Ac contactor | schneider | The French | 1a | Control pump motor |

| Motor breaker | schneider | The French | 1a | Protect pump motor against Overload, short circuit, phase loss |

| Motor breaker | schneider | The French | 1a | |

| Proximity switch | Xin ling | Zhejiang | 1a | Control sterilization to be carried out safely |

| Leakage circuit breaker | schneider | The French | 1a | Electric leakage protection |

| The circuit breaker | schneider | The French | 1a | Control power protection branch circuit |

| Switching power supply | schneider | The French | 1a | Provide stable power supply |

| Intermediate relay | schneider | The French | 1a | Control circuit |

| Wiring row | chint | Zhejiang | 1a | |

| Modular socket | chint | Zhejiang | 1a | |

| Alarm red green yellow light | Tianjia | Shanghai | 1a | Prompt operator |

| Alarm buzzer | Ergong | Shanghai | 1a | Send out an alarm to remind the operator |

| Indicator light | chint | Zhejiang | 1a | According to the signal |

| Key switch | chint | Zhejiang | 1a | Responsible for starting and stopping the equipment |

| Scram button | chint | Zhejiang | 1a | |

| With lamp button | chint | Zhejiang | 1a | Command inputs |

| With lamp button | chint | Zhejiang | 1a | Command inputs |

| Selected switch | chint | Zhejiang | 1a | Selective control system |

二、Sterilization pot equipment features:

1、Sterilization pot to suit range

1)Plastic containers: PP bottles, HDPE bottles.

2)Soft bag packing: aluminum foil bag, high temperature cooking bag, high temperature vacuum bag, etc.

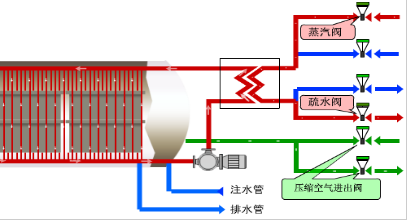

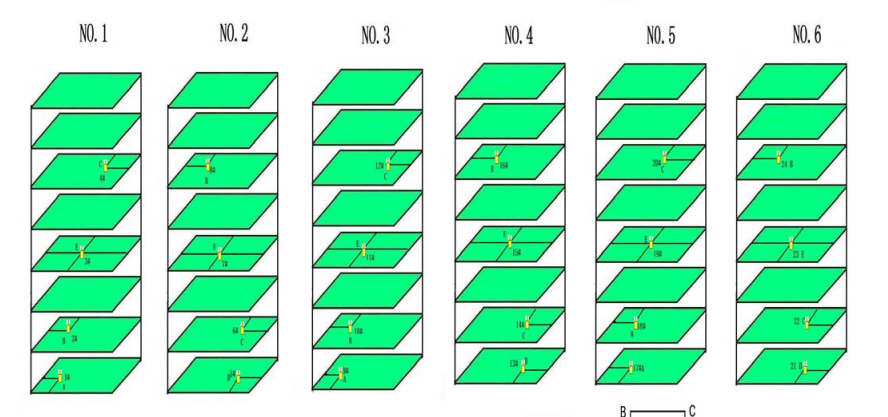

2、Working principle diagram

3、Bactericidal characteristics:

1)The germicidal water is poured from the packaging of the germicidal pot through the large-flow circulation pump. Because the germicidal water is preheated in advance, the temperature of the first packaging of the germicidal product is almost the same, effectively avoiding the temperature fluctuation caused by the instant contact between the germicidal water and the material, causing the change of packing material pressure and the phenomenon of rise or shrinkage.

2)High efficiency heat exchanger reduces steam consumption and quickly reaches predetermined sterilization temperature.

3)Indirect heating indirect cooling, cooling water and process water do not contact, to avoid secondary contamination of food, no need for water treatment chemicals. High temperature short time sterilization.

4、The choice of temperature position

Compared with the traditional sterilization, the requirement is the uniform distribution of heat in the pot, and the measurement is the temperature of hot water or steam in the pot, so the thermometer is generally placed in the center of the pot. The mercury thermometer of Hengshi Company is on the outlet at the bottom of the pot. What is measured by the water-spraying sterilization is the position of the most cold point in the sterilization kettle. When the position of the most cold point reaches the sterilization temperature, it also meets the constant temperature sterilization temperature required by all products in the sterilization kettle.

According to the NFPA, 26 - L bulletin and China national standard SN/T0400.6-2005 import and export of canned goods inspection procedures for part 6 mercury thermometer requirements: the legal indicating instrument of sterilization temperature for glass mercury thermometer, other control with temperature sensor and temperature recorder must be adjusted to the same as the mercury thermometer as far as possible, but must not be higher than the mercury thermometer.

5、The sterilizing pot's air exhaust pipe is connected in series in a centralized way to facilitate customers' centralized arrangement of connecting compressed air pipe and exhaust pipe. The connection mode of this air exhaust pipe is to reduce the need for multiple compressed air and exhaust pipes before. Second, the pipeline distribution is simple and clear, both beautiful and save cost, reduce leakage points.

6、The pressure gauge of sterilization pot adopts axial pressure gauge, which is fixed on the leg of sterilization pot. It is more stable and accurate than the pressure gauge installed on the sterilization pot body.

7、Partition secondary pollution

The sterilizing water in the pot is indirectly cooled by the heat exchanger. The warm water does not touch the sterilizing water in the pot, so the cooling water in the pot will not be polluted and chlorinated cooling water is not needed. The soft water in the pot can be used repeatedly, which saves water and blocks the outside pollution to the packaging inside the pot.

8、Highly automated

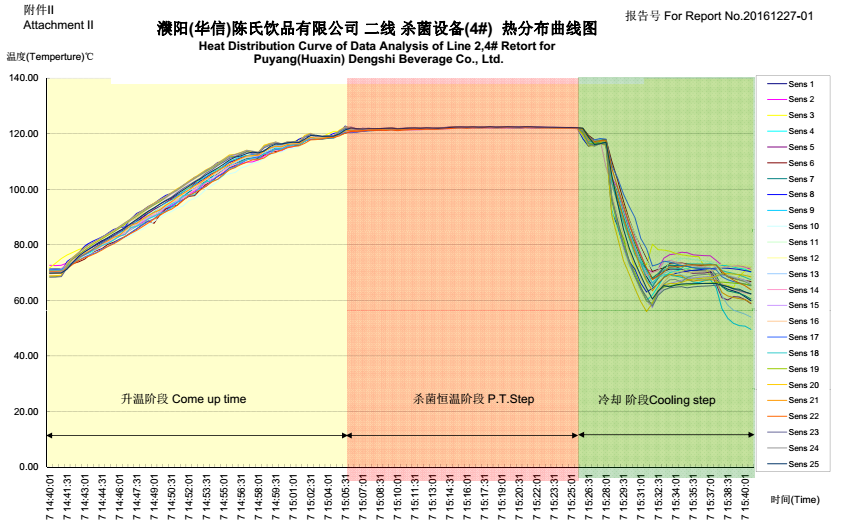

The whole sterilization process control can be completed on the touch screen, sterilization process requirements such as temperature, time, sterilization pressure, cooling pressure, cooling temperature and sterilization intensity F value display functions can be customized according to different models. The temperature control precision can reach ±0.2℃, and the pressure control precision can be plus or minus 0.01Mpa. Can store hundreds of sterilization process procedures, greatly reduce the fatigue strength of operation, improve production efficiency.

9、Twenty-four point temperature difference (thermal distribution) curve and probe location diagram

10、Pressure vessels are designed, manufactured and accepted in accordance with national standard GB150-2011. The equipment complies fully with GMP standards and FDA requirements.

11、 The best quality flange and sealing parts in China are used. The head is formed by one time cold pressing, and after aging vibration, there will be no stress deformation during use.

12、 Advanced and stable SIEMENS control systems ensure customers find supply chains in a timely manner and reduce downtime globally.

13、 The industry's rare high - end equipment and strict production process control management, to ensure the quality of the machine.

14、The overall design and layout of the equipment is reasonable, safe and reliable. It is convenient for operation and maintenance of equipment. Electrical appliances and control system are used foreign well-known brands, to ensure the stability of the entire control system, so that the sterilization process is more safe and stable.

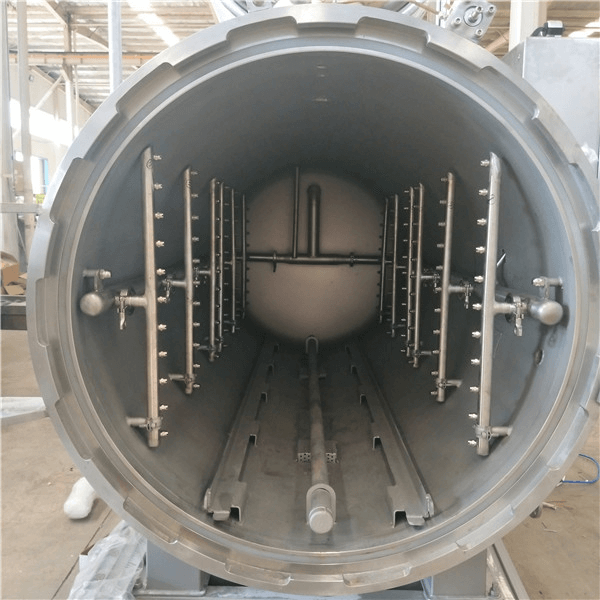

三、Equipment details

| serial number | Name | Refer to the drawing or presentation | Advantage performance description | place of origin | |

| 1 | cylinder |  |  | Made of baosteel stainless steel; Submerged arc welding, double-sided welding molding, to ensure penetration; Avoid equipment cracking caused by welding defects; | Baosteel/Shanghai |

| 2 | head |  | One - time stamping forming, using advanced technology to eliminate stress; It has the characteristics of uniform thickness and long service life. | Zhengtong/Jiangsu | |

| 3 | The flange |  | Roll ring flange; After heating the whole ingot, it is rolled into shape once without welding. After aging treatment, it is finished by finishing processing. (95% sterilization pot manufacturers use forging welding flange, easy to crack, there is the risk of explosion | ZhangqiuHuabao | |

| 4 | Open the door device |  | The pot door is equipped with a gasket vacuum return device, which can switch easily and seal well. And equipped with triple safety interlock device to achieve 100% safety of operators; | HengShi company | |

| 5 | Pressure balancing device | Patented device, pictures shall not be displayed | The new pressure stabilization system keeps the pressure in the pot extremely stable and reduces the influence of compressed air injection on the temperature in the pot. | HengShi company | |

| 6 | The device starts the protection |  | One-button startup, foolproof operation; Cannot start up if the operating conditions are not reached; All the control and display devices are centralized on the center console, so there is no need for personnel to operate in close proximity, which ensures the safety of personnel. | HengShi company | |

| 7 | Operation safety protection device | ||||

| 8 | Positive pressure overpressure relief device |  | Triple mechanical safety valve protects the equipment from being damaged or scrapped due to pressure exceeding during operation. Double device is to prevent the safety valve fault in the case of accidents; And also equipped with artificial emergency discharge valve, to ensure 100% safety; | HSBC/Qingdao | |

| 9 | High and low temperature warning device | Program control | When sterilization is carried out, the actual temperature shall be compared with the set temperature. When the fluctuation is too large, it will automatically alarm and stop; Ensure product safety | HengShi patent | |

| 10 | High and low pressure warning device | Program control | When sterilization is carried out, the actual pressure is compared and the power is set. When the fluctuation is too large, it will automatically alarm and stop. Ensure product safety | HengShi patent | |

| 11 | Temperature contrastive analysis unit | Program control | There are two temperature sensors installed on the equipment. When sterilization is carried out, one is for sensing function and the other is for monitoring. Once the temperature does not match, the equipment will immediately alarm and suspend the processing. | HengShi patent | |

| 12 | The water pump |  | Circulating water pump with large flow and low head; Make the running state of water pump reach the best, thus reduce the power consumption waste; | Bihu/Shanghai | |

| 13 | Plate heat exchanger |  | 1. Imported EPDM gaskets are used for heat exchanger gaskets, which have higher temperature resistance than those of other domestic manufacturers, and the temperature resistance value can reach more than 200℃. 2. High heat transfer coefficient. 3. Compact structure, easy to disassemble, clean and maintain. 4. Small dirt coefficient. 5. Small floor space. 6. Better cooling effect than tube heat exchanger (the product can be cooled from 121℃ to 38℃ within 20 minutes) | Daniel/Shanghai | |

| 14 | Float ball trap |  | Steam trap is used in the steam pipe network and equipment, can automatically discharge condensate, air and other non-condensable gases, and prevent water vapor leakage valve, steam trap in the steam heating system to prevent steam drainage | Special one/Shanghai | |

| 15 | The filter valve |  | Used to remove impurities from pipes and steam and to protect the normal operation of valves and equipment | Special one/Shanghai | |

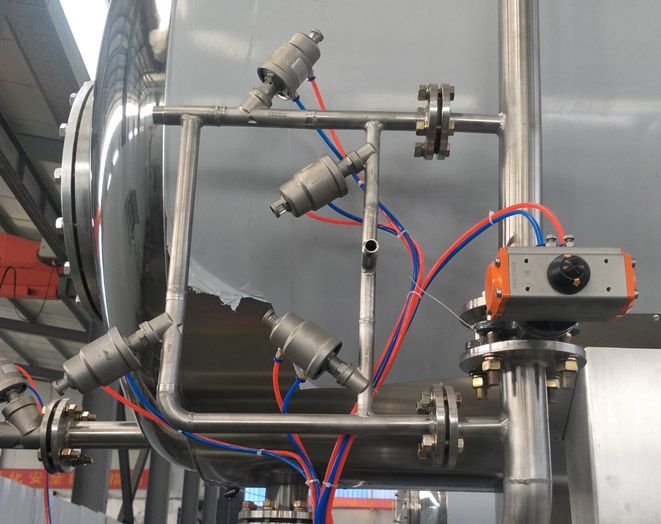

| 16 | Pneumatic butterfly valve |  | 3 million pneumatic actuators; The sealing ring is made of special materials according to the special working conditions of the sterilization equipment of our company. It is resistant to high temperature, high pressure, water and easy to be replaced. | Central Control/Shanghai | |

| 17 | Pneumatic Angle seat valve |  | Open the pneumatic actuator 3 million times; Good durability, high control accuracy, accurate control of steam and compressed air injection volume; | Jing Cheng/Shanghai | |

| 18 | The wafer The check valve |  | Prevent backflow of water and gas Customize according to actual needs | Special one/Shanghai | |

| 19 | Pipe fittings such as pipes and flanges |  | Customize according to actual needs | Yongshang/Zhejiang | |

| 20 | Aluminum silicate |  | 30mm aluminum silicate, low bulk density, low heat capacity,. Superior holding stability, good anti-pulverization ability, excellent heat insulation, sound absorption effect. Low heat storage and thermal shock resistance. | HengShi company | |

| The control system | |||||

| 21 | The man-machine interface |  | One-button operation, touch control, sensitive reaction; With sterilization curve preservation function; | Siemens/Germany | |

| 22 | Programmable controller |  | It has strong control function and strong computing power. It can not only complete the general logical operations, but also more complex trigonometric functions, exponents and PID operations. The working speed is relatively fast, the use is stable, the life is long; | Siemens/Germany | |

| 23 | Temperature sensor |  | High precision, good durability, signal transmission device with stainless steel hood protection, avoid electromagnetic interference; Long service life; | Yunqi Instrument/Shandong | |

| 24 | Pressure sensor |  | It has the highest specification for compact structure, long life, high precision, temperature stability and electromagnetic compatibility. | HUBA/The Swiss | |

| 25 | Electrical components |    | High stability, sensitive response, is the current market circulation of the most stable electrical components; | Schneider/France | |

| 26 | Solenoid valve |  | With automatic control and manual operation device, long service life, high stability, easy to replace; | Delixi/Zhejiang | |

| 27 | Gas-water separator |  | Can effectively separate water, impurities and air in compressed air; In addition, it is also equipped with a set of automatic oil filling lubrication device, which can automatically maintain and lubricate the piston of pneumatic valve during operation. | ChengDi pneumatic | |

| 28 | Air flow controller |  | The main pneumatic valve controller is equipped with flow controller, according to the requirements of the product process, set the valve opening speed, and reduce the impact of wear and tear on the valve, improve the service life of the valve; | Shanghai | |

| 29 | Pressure gauge |  | The pressure gauge can accurately indicate the level of steam pressure in the pressure product. The operator can adjust the heating degree of the product according to the indicating value of the pressure gauge to ensure the requirements of the gas department and the safe operation of the pressure product. | East Airlines/Weifang | |

Technical Service Contents

1. Provide relevant industry information for free.

2. Provide the graphic design and relevant equipment configuration for free.

3. Answering technical and business questions on site for free.

4. Free installation and debugging of equipment and standardized training of users' operation and maintenance personnel.

Service commitment

1. Guarantee the quality of the whole equipment purchased for one year.

2. Open a 24-hour service hotline (0536-6187855), pay regular return visits and accept customer inquiries.

3. Handled timely after receiving the customer's call.

Some successful projects

(Duck blood production Line of Chengdu Qiaoya Qiaoqiao Food Co., LTD.)

Chengdu Rice Sweep Food Co., LTD. (Glass bottle)

Mianyang Mixiaofu Food Co., LTD. (Deep Processing of meat Products)

Taizhou Yellow Can Michelin Food Co. LTD. Production line

Note: The above cases are some successful cases of customers, which are not listed here

Copyright © ZHUCHENG BAOZHIFENG MACHINERY CO., LTD. All Rights Reserved |

Sitemap

|

Powered by