After installing the mixing bin, this machine will complete all the actions automatically such as lifting, mixing and descending. An automatically-lifting bin mixer and several mixing bins of different specifications can meet the mixing requirements of diversified varieties and different batches of products.

PRODUCT DESCRIPTION

Features of HTD Series Column Bin Mixer

After installing the mixing bin, this machine will complete all the actions automatically such as lifting, mixing and descending. An automatically-lifting bin mixer and several mixing bins of different specifications can meet the mixing requirements of diversified varieties and different batches of products. It is an ideal machine for mixing in pharmaceutical plants. It is also widely used in such industries as medicine, chemical industry, food, etc.

The machine is composed of machine base, rotation body, lifting system, braking system, and control system. After pushing the mixing bin into the mixing crotch, the bin is locked tightly by the locking handle. Through the automatic control function on the touch panel, the bin will be lifted to and stop at the mixing position. Then the mixing system will work. The mixing system will carry out mixing according to the set time, rotation speed and other data. After reaching the set parameters, the mixing bin will stop vertically and meanwhile the braking system starts. Then the lifting system will lower the bin to the ground. After the bin is lowered to its position and stops, the process data will be printed. The bin is ready to be pushed out and transferred to the next procedure.

The machine is a new machine researched and developed successfully by our company according to China's actual conditions after absorbing and digesting internationally advanced technology. After mixing is finished, the hopper can continue to rise to the required height to facilitate discharging. The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts. The gyrator (mixing hopper) forms an included angle of 30° with the rotation axis. The materials in the mixing hopper rotate along with the gyrator and make tangential movement and achieving the best mixing effect. PLC automatic control is adopted. It is provided with the infrared safety device and the discharging butterfly valve with the misoperation preventer to ensure safe production. The material can go through different working producers in the same vessel without the need of frequent material transferring, material charging, etc. The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets the requirement for medicine production in GMP.

1. Safety

1) Safe Hydraulic Block

2) Falling Prevention when tubing bursts

There is one-way safety valve in the hydraulic cylinder. When the tubing bursts, the one-way safety valve and discharging port of oil cylinder will close to prevent the trolley falling danger caused by the pressure relief of oil cylinder.

3) The upper and lower parts of the column are fixed, which improves the overturn-preventing capability and safety.

4) The main structure of the lifting column is made of forklift mast steel. The guide rail has thick material and high strength, which prolongs the life of the guide rail and satisfy the requirements of the lifting and loading.

5) There are upper and lower limit devices in the machine, to ensure the safety of lifting machine.

6) External safety lock. When the device is in high load for a long time, it is effective to prevent accidental fall after the safety lock is opened.

7) The lifting trolley in the lifting column is equipped with built-in anti-falling device. When the lifting chain is broken, the anti-falling device can effectively clamp the trolley to the column, and effectively prevent the secondary dangerous occurrence of the chain fracture.

2. Stability

1) HTD Column Bin mixer adopts single column base design with upper and lower parts fixed, which saves space. The rotary force of the base is in good condition. The ground load is uniform. There is no special requirements for the base. The equipment runs smoothly.

2) The column is equipped with lifting power and rotary power devices, which have simple structures, large space and convenient maintenance. Lifting relies on the hydraulic system of oil cylinder, which is safe and reliable.

3) Lifting system adopts the oil cylinder hydraulic system and centralized hydraulic valve components, to ensure the reliable operation of valve group. It is easy to maintain, reduces the complex oil circuit and has small volume.

4) Mixing rotary adopts the design which integrates the motor, reducer and brake system. It has the advantages of few transmission parts, small volume, and simple maintenance.

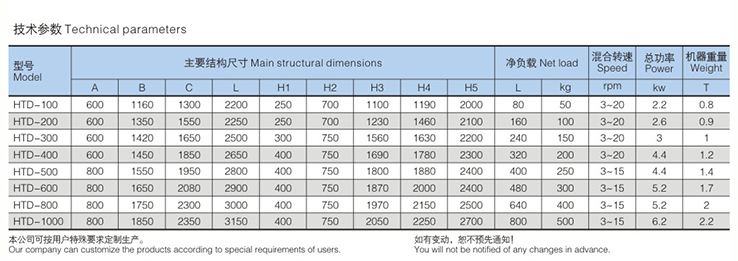

5) This machine adopts the PLC control system. It is able to complete all the operations automatically based on the set process parameters and print all the results automatically. The original record is true and reliable. This machine can set different speed and mixing time according to different flow characteristics to obtain the best mixing effect. The speed setting range is 3-8rpm, and the mixing time setting range is 0-59min. The touch panel has a very friendly Chinese and English interface.

6) The machine has a perfect sensor control system, which can guarantee the automatic operations of mixing bin lifting, automatic deceleration and stopping alignment, and the process is stable and accurate.

3. Meeting the requirements of the pharmaceutical industry

1) The machine has no dead angle, no convex and concave plane, and exposed screws, which is easy to clean.

2) The surface in contact with the drug is polished with high precision. The roughness can reach Ra≤0.2um. The outer surface is treated with matte finishing and the roughness can reach Ra≤0.4um, which is easy to be cleaned, and in full compliance with the GMP requirements of drug production.

3) Configuring the mixing bins with different volumes can meet the requirement of multi-variety and mass production. It is able to serve as multi-purpose and improves the production efficiency.

Structure Characteristics

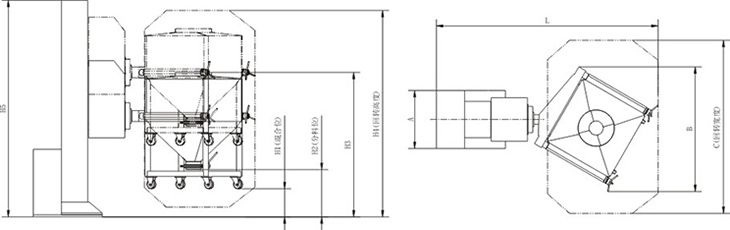

1. Rotary base 2. Electrical control box 3. Control Panel 4. Lifting oil cylinder

5. Lifting Trolley 6. Anti-falling device 7. Lifting chain 8. auxiliary support

1) The column base consists of mounting base, column, cord fabric and accessory parts. The base is fixed to the ground, the column is fixed on the base, the base and the column are welded together with the high quality structural steel, the column and the base surface are treated with the spray paint after rust removal, and the outer cover is made of 304 stainless steel sheet. The column is the supporting body of the whole machine, and the lifting system and hydraulic power control system are installed on the column. The trolley passage in the positive side of the column is sealed by the cord fabric to separate the components from the working environment, which meets the GMP requirements.

2) Lifting System

Lifting system consists of lifting cylinder, lifting chain, and lifting trolley and so on. Lifting cylinder is the core part of lifting system. The lifting chain pulls the trolley to realize the crotch lifting and descending along the column.

3) Mixing Rotary System

The mixing rotary device is installed on the trolley, which is the key system of mixing. It is mainly composed of mixing reducer, mixing positioning proximity switch component, mixing transmission device, mixing crotch rod, bin locking device, etc. The mixing reducer adopts the domestic famous brand and adopts the integrated helical gear reducer with low speed and high torque. The mixing reducer drives the mixing crotch, which has the characteristics of simple structure and high transmission efficiency. The bin is integrated into the rotary system by means of the insertion rod, bin locking device and rotary system.

4) Hydraulic System

Hydraulic system consists of power unit (pump group), control elements (valve group), actuator (oil cylinder) and various accessories (tubing, joints, pressure gauge, liquid level meter, filter, etc.).

5) Electrical control box

The electrical control system consists of two parts: electric control box and sensor. The sensor has micro switch, travel switch and etc. in the machine. The core control element is installed in the electrical control box. The operation of the machine is done through the panel mounted on the control box.

Copyright © ZHUCHENG BAOZHIFENG MACHINERY CO., LTD. All Rights Reserved |

Sitemap

|

Powered by